Our services

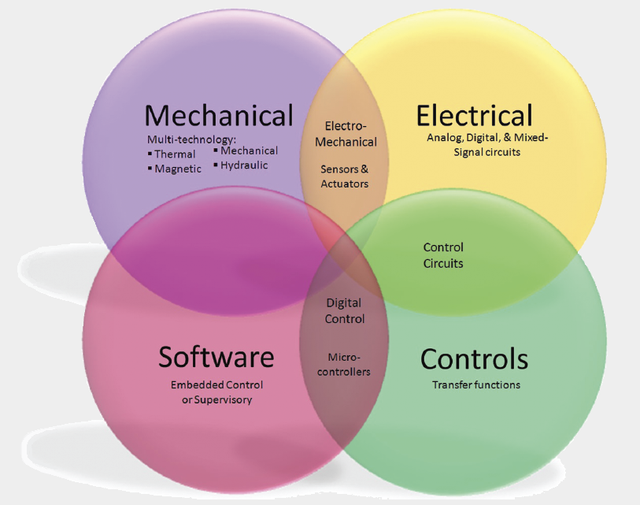

multidisciplinary projects

This is where we stand out!

If your project requires a mix of the below mentioned disciplines we'll carefully examine your project to find the best balance between the use of mechanical, electronics and software solutions to give you the most efficiënt solution possible!

We'll start a project with an intake to discuss your project needs. Whether this is a design for a complete new system, an upgrade from an existing system or just analysing a system with the goal of improving it:

we can support!

Of course, when your project only asks for a monodisciplinary approach we can also support!

Mechanical

We can perform full mechanical design being static columns up to complicated dynamic drives. We use modern 3D CAD solutions for all our designs. Calculations/simulations of all kinds are also possible.

We specialize in compact mechanical systems and are able to make prototypes in our own workshop. We are experienced but not limited to the following manufacturing processes:

- Machining, conventional and CNC (in our own workshop)

- Carbon and glasfiber laminated structures

- Rotation moulding

- Rapid prototyping (3D printing)

- Sheet metal (laser/waterjet/bending)

- Welding (MIG/MAG/TIG)

- For other processes we're always able to find a production partner

Electronics

If your project needs control by electronics we can support by converting your needs in to functional descriptions, prototypes, hardware (PCB) design, wiring looms etc.

The first ideas are normally tested using breadboards and prototype systems. From there we proceed drawing the final schematics ending with a complete PCB design.

For PCB manufacturing we make use of careful selected partners that suit the project needs in terms of cost and quality.

Software

If your project needs software we can support with embedded software (AVR/microcontroller) and PC software utilities. (.NET C#)

The PC utilities that we write are often interfacing to hardware that we designed for a project. The utilities are often used for configuration of the hardware or to show data from the hardware on a screen, enabling it to be analysed and stored on a PC.